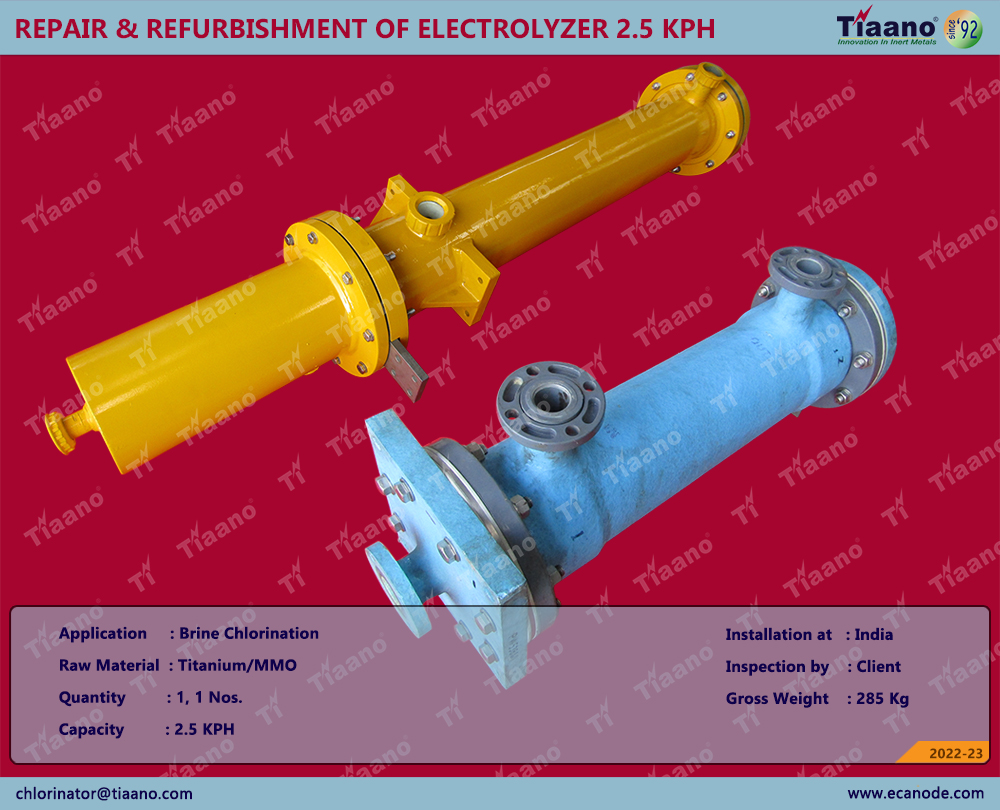

Repair and Refurbishment of Electrolyzer for Brine Chlorination

July 30, 2022 at 2:55 PM

—

admin

Refurbishment projects have increased as more and more companies look for cost saving solutions for their existing plant thereby maintaining the uptime, reducing downtime rather than going for the expense of a new build or extension. We work within many electrochemical sectors including Chlor-alkali, hypochlorite, chlorate, waste water treatment. From basic to detail engineering, concept to completion, the refurbishment program will be managed by Titan, working closely with experts and audited on a regular basis.

The anode and cathode assemblies (electrodes) are critical design features of an electrolyzers, and must be manufactured from special materials to prevent corrosion by the chlorine.

The anode is where the chlorine is generated and was historically manufactured from graphite or platinum alloys. Modern electrolyzers feature anodes made from titanium for corrosion resistance. The cathode element is typically less sensitive to corrosion, and is often manufactured from nickel, although stainless steel can be used.

Additionally, each electrode is coated to improve power performance and efficiency of the electrolysis process.

- Cathode pan coatings electro-catalytically promote H2 evolution and provide resistance to impurity poisoning and reverse currents at shut-down.

- Anode pan coatings are for the electro catalytic promotion of Cl2 evolution and have superior alkali wear performance and lower exit brine chlorate values

Contact us : chlorinator@tiaano.com

Mobile no : 9382512010