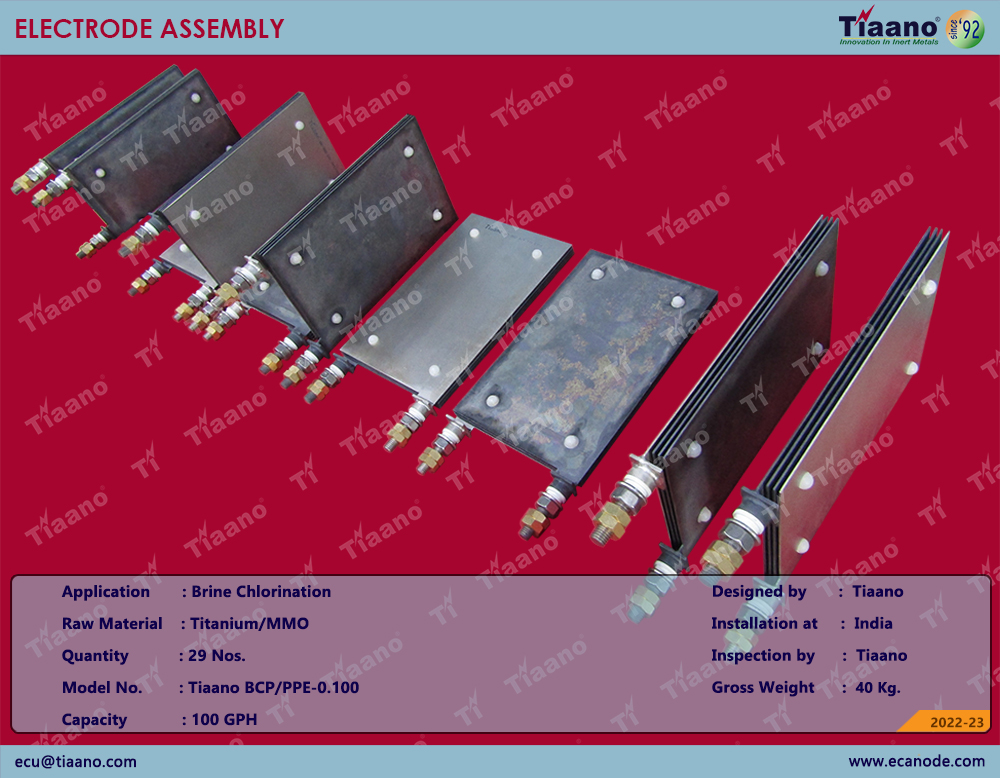

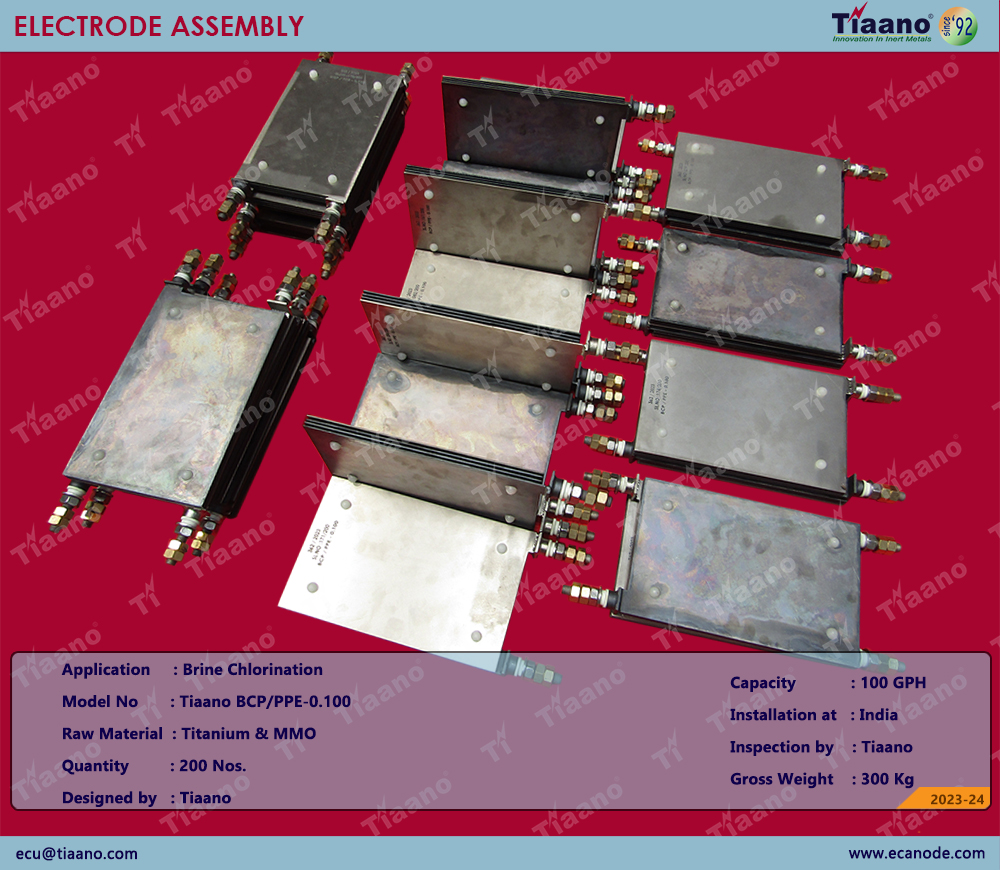

Manufacturing and Supply of Electrode Assembly 100 GPH for Brine Chlorination.

December 30, 2022 at 10:22 AM

—

admin

Treatment for drinking water production involves the removal of contaminants from raw water to produce water that is pure enough for human consumption without any short term or long term risk of any adverse health effect. In general terms, the greatest microbial risks are associated with ingestion of water that is contaminated with human or animal (including bird) excrement.

Excrement can be a source of pathogenic bacteria, viruses and other microorganism that can cause disease. Substances that are removed during the process of drinking water treatment, Disinfection is of unquestionable importance in the supply of safe drinking-water.

The destruction of microbial pathogens is essential and very commonly involves the use of reactive chemical agents such suspended solids, bacteria, algae, viruses, fungi, and minerals such as iron and manganese. These substances continue to cause great harm to several lower developed countries who do not have access to water purification.

The Chemical reaction is:-

NaCl + H2O + Energy = NaOCl + H2

Brine is a solution of sodium chloride (NaCl) and water (H2O). The process of electrolysis involves using an electric current to bring about a chemical change and make new chemicals. The electrolysis of brine is a large-scale process used to manufacture chlorine from salt.

For Enquiries: ecu@tiaano.com

HP : +91 9382535082

Facebook Twitter Instagram Pinterest