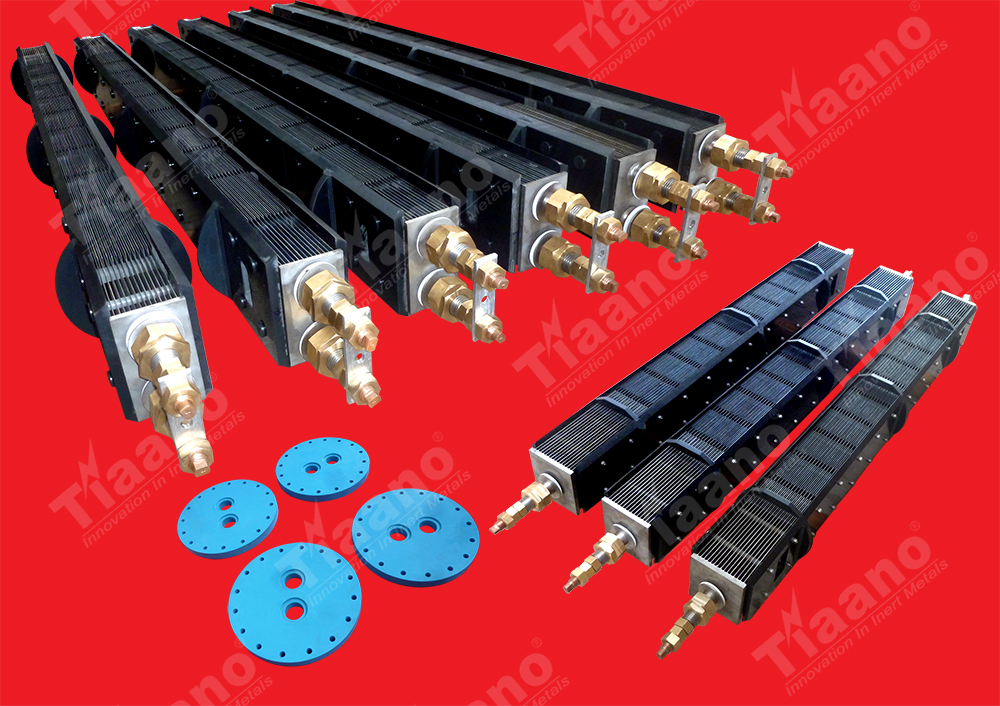

Electrolyzer for Sea water chlorination – Power plants

Tiaano, India established in 1992 into designing, manufacturing and supply of PPE, CTE, PPME, Bi-polar, Mono-polar & Reverse polarity ELECTROLYZERS (assembly of anode & cathodes) for Electrochlorinator Anodes are made from Titanium substrate with the Ru based DSA activation. Cathodes are made from the substrates of Titanium, Hastelloy or Steel. The range of chlorine production capacity of single electrolyzer is starting from few grams to 250 kilograms per hour (6000 kgs/day). We meet the higher capacity plants by multifold arrangement of said electrolyzers. We design the cells to consume 3.5 to 5.0 DC Voltages, with the 5 years life warrantee for DSA activation, life may extended further two years, based on proper periodical maintenance. Our electrolyzers generate hypo with the highest chlorine concentration that is economically viable.

Over 2,000 installations are performing all over the world, Customers are supported through an international network of agents in over 40 countries. For your further understanding, please visit our site www.ecanode.com We offer the following components / Products / spares for Electrochlorinators.

1). PPE, CTE & PPME Electrolyzers [an assembly bundle of DSA Titanium Anodes and Cathodes] made from any forms like plate, tube, mesh and custom fabricated of titanium and nickel alloy substrates. 2). Monopolar anodes, cathodes and bipolar electrodes as a spares for the electrolyzers. CPVC, Clear PVC, PVC with GRP and Rubber (Ebonite) lined CS Electrolyzer Housings. 3). PTFE (Teflon), Silicon, Neoprene, EPDM Gaskets. 4). PVDF, PTFE, PVC Spacers. 5). Titanium, Steel, Copper & Brass Hard wares. 6). Titanium Coolers to maintain the Hypo temperature between 5 to 27 degree C. 7). Titanium Pipes, fittings & distribution nozzles. 8). GRP pipes or Titanium lined GRP pipes for seawater transfer. 9). Teflon (PTFE) / Rubber Bellows. 10). Titanium earthing electrodes. 11). Hydrogen Degassing Tank / Venture. 12). FRP Hypo Storage Tank. 13). Acid Washing System. 14). Online Chlorine Analyzers. 15). Electrochlorinator System Skids.

Replacement / Refurbishment capacity of Tiaano

We expertise for the replacement or refurbishment of electrolyzers & other spares for Electro chlorinators, where the project executed by the following World Leaders, namely…

- M/s. Seven Trent De Nora, USA [Chlortec, Seachlor, Sanilec, Omni pure Balpure]

- M/s. Siemens, USA [US Filters, Chloropac, Sanichlor, OSEC, Seapac, Electrocatalytic].

- M/s. Daiki, Japan.

- M/s. Mitsubishi, Japan.

- M/s. Cumberland, UK.

- M/s. Pepcon, USA.

- M/s. Sespi, Italy.

- M/s. Nippon, Japan.

- M/s. Electrichlor, USA.

- M/s. Charles Thompson Limited, UK.

- M/s. Sal-Chlor, Australia.

- & many more unlisted companies too.

We are supplying Electrolyzers nearly 63 countries. Our recent supply of PPE (parallel plate Electrolyzers) model to Udupi Power corporation Limited , India .

Electrolyzer 16.5 kph & 6 kph