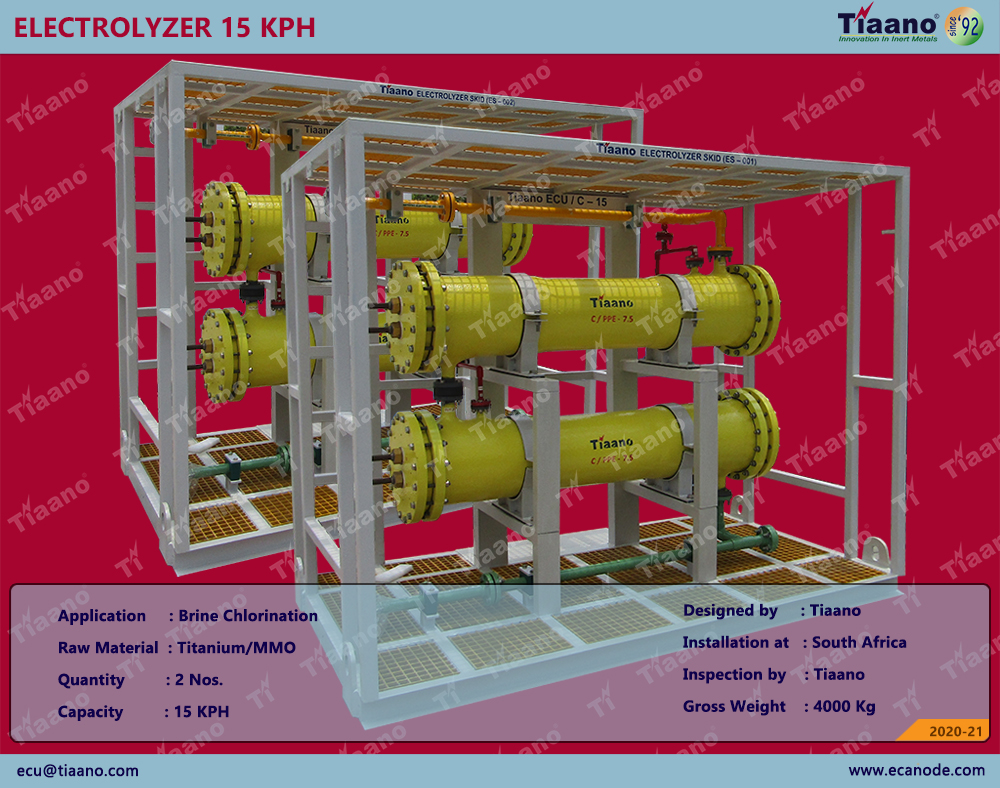

Design, Fabrication and Supply of Electro Chlorination Plant 15 KPH for Brine Chlorination.

July 18, 2022 at 9:06 AM

—

admin

Tiaano an ‘ISO 9001 : 2015’ organization incepted on 1992, installed over 5000 Electrochemical water treatment systems in 63 countries. We Design, Manufacture, Supply and Commissioning on-site Electro Chlorinators for disinfection of drinking water in various water boards like Public Health Organisation, Corporations, Municipalities and Panchayats. In addition, our Electro Chlorination Plants are getting installed in Swimming pools, mining Industries, Power stations, Chlorine plants, marine vessels and a wide range of industrial process in the brand name of Tiaano. Using our unique TITANIUM NOBEL METAL ELECTRODE & patented electrochemical processes, we manufacture the systems, having the Cl2 production of 6.25 GPH to 1000 Kgs/Hr.

PROCESS OVERVIEW:

‘Tiaano ECU/C -15’ Plant is designed to produce 15 KPH of available chlorine per hour in the form of sodium Hypochlorite solution by the electrolysis of Brine solution. Concentrated brine solution 300 gpl (grams per liter) is prepared in brine preparation tank. The concentrated brine solution and chilled water are then mixed together in the mixing chamber to form diluted brine solution 30 gpl (grams per liter) before it is fed into the Electrolyzer. Soft water cooling takes place at chiller, before fed into the mixing chamber.

The concentration of the brine solution will depend on the amount of chilled water being fed through the Magnetic Flow Transmitter (MFT). The electrolyzer are connected both in hydraulic and electric series. D.C current roted at maximum amps is passed through the series of cells through a transformer rectifier unit. It is fed from the (+) output terminal to the anode of the electrolytic cell and passes anodes through DC busbars. Inside the electrolyzers the mixture undergoes a partial electrolysis of the sodium chloride contained in it and the result is a chlorinated brine solution called Sodium hypochlorite containing hypocholrous ions and hydrogen gas. The finished product coming out from the electrolyzer is fed into the hypochlorite storage tank (customer scope) and only hydrogen gas is separated and diluted by air blower. Sodium hypochlorite is an efficient disinfectant that provides odourless, safe and germ-free drinking water.

1. ELECTROLYZER SKIDS.

2. SKID MOUNTED CHILLER UNIT.

3. SKID MOUNTED ACID CLEANING SYSTEM.

4. SKID MOUNTED BRINE FILTRATION UNIT.

5. SKID MOUNTED BRINE DOSING UNIT.

4e52a589-145f-4ea8-aa27-ea5ed102b00d|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

Posted in: Acid cleaning | Bi-Polar | BRINE BASED | brine chlorination | Brine Dosing | Brine Filtration | cathode | CHLORINATOR | disinfection | drinking water | Electrochlorinator | electrolyzer | Skid | sodium hypochlorite | TIAANO

Tags: Tiaano, Brine, Water, Skids, Disinfection, Filtration, Cleaning, Dosing, Electro, Chlorination, plant.